A point was raised this week that that we would like to discuss. PUMP VOLTAGES.

Swiwin announced some months back that the pump voltages had changed. The pumps and ECU coding have been modified and may require lower voltages than before. What does this mean? If you receive an engine from us and your pump voltage is set to .3 or .4, this is not a mistake and should not be treated as a mistake. We are very concerned that in the event that a user mistakenly adjusts his/her pump voltage to the customary .6 voltage that a fire could result. How do we know this? Well, we tried it and we had a small controllable fire that resulted.

Other questions have been raised.

1. Should I change the value of pump start for my older engine? No do not make any changes.

2. Does this have to do with coding recent changes to the ECU? Partially yes. There have been improvements to the pump and the ECU hardware and coding has changed.

3. If I purchase a spare or replacement pump, do I need to change the setting? This is a very good question. If hardware is changed for a turbine, always air on the side of caution and be prepared to perform a shutdown if needed. Once any adjustments are made then this will not need to be done again. If you connect a new pump to an older engine/ecu you should not need to make any changes. Also remember to retrain the engine whenever hardware is changed meaning learning full thrust.

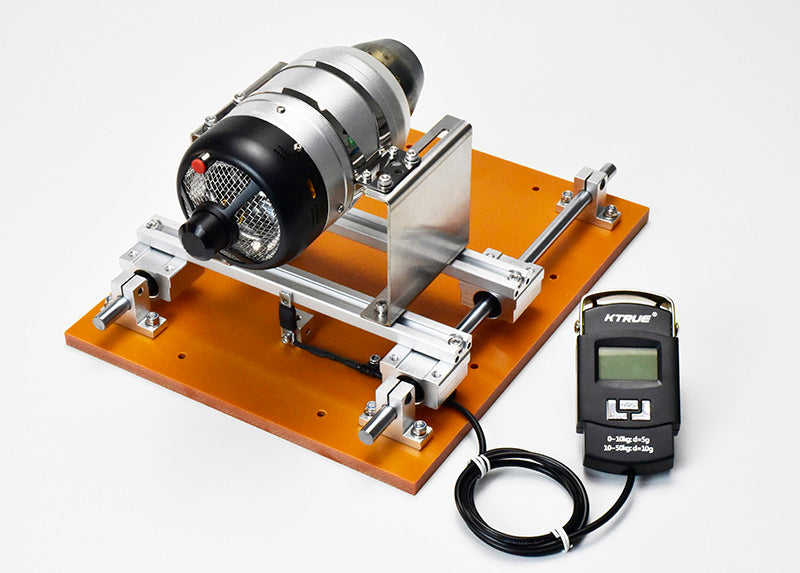

There are some essential common sense things about running a turbine. Turbines are inherently dangerous to run. Burns are the most common type of injury that can occur. We don't take this likely. Every turbine sold by CRX is tested for proper operation and good balance before they are sent out to our customers. We pioneered this rationale of service protocol by testing factory engines when we worked with JetJoe.